The Company

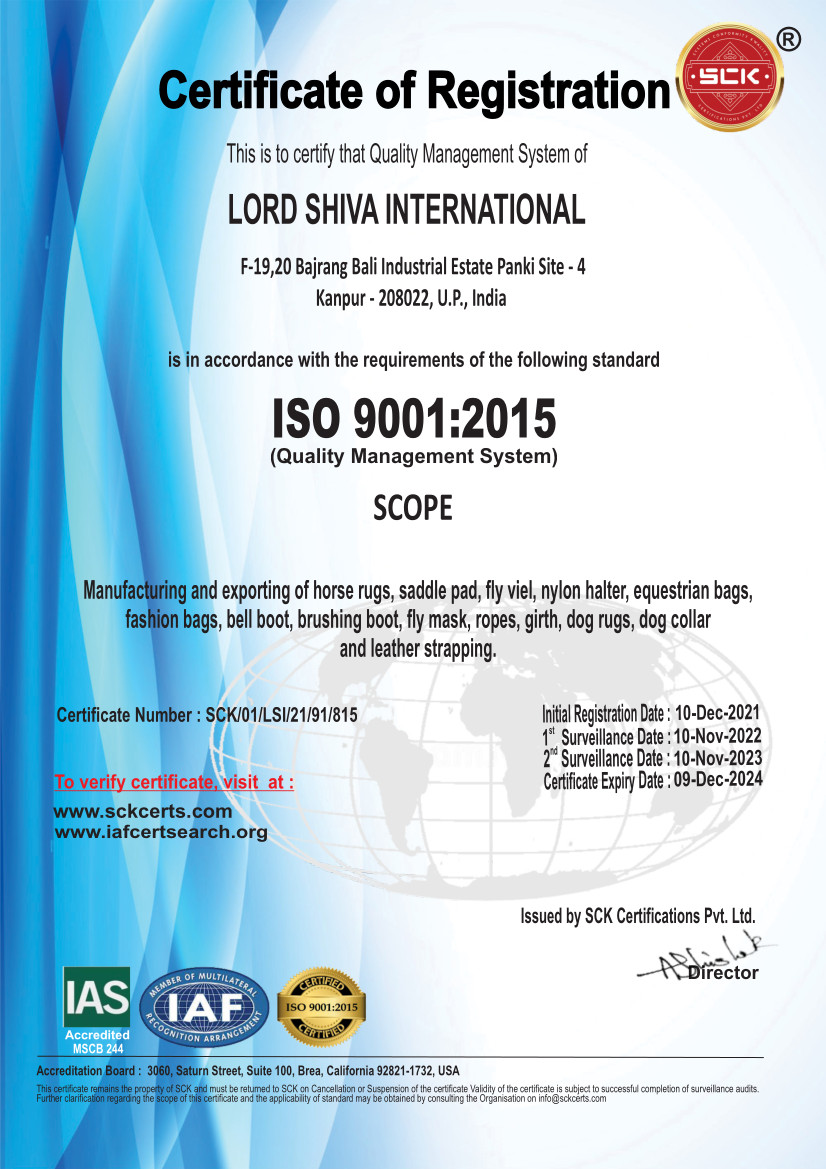

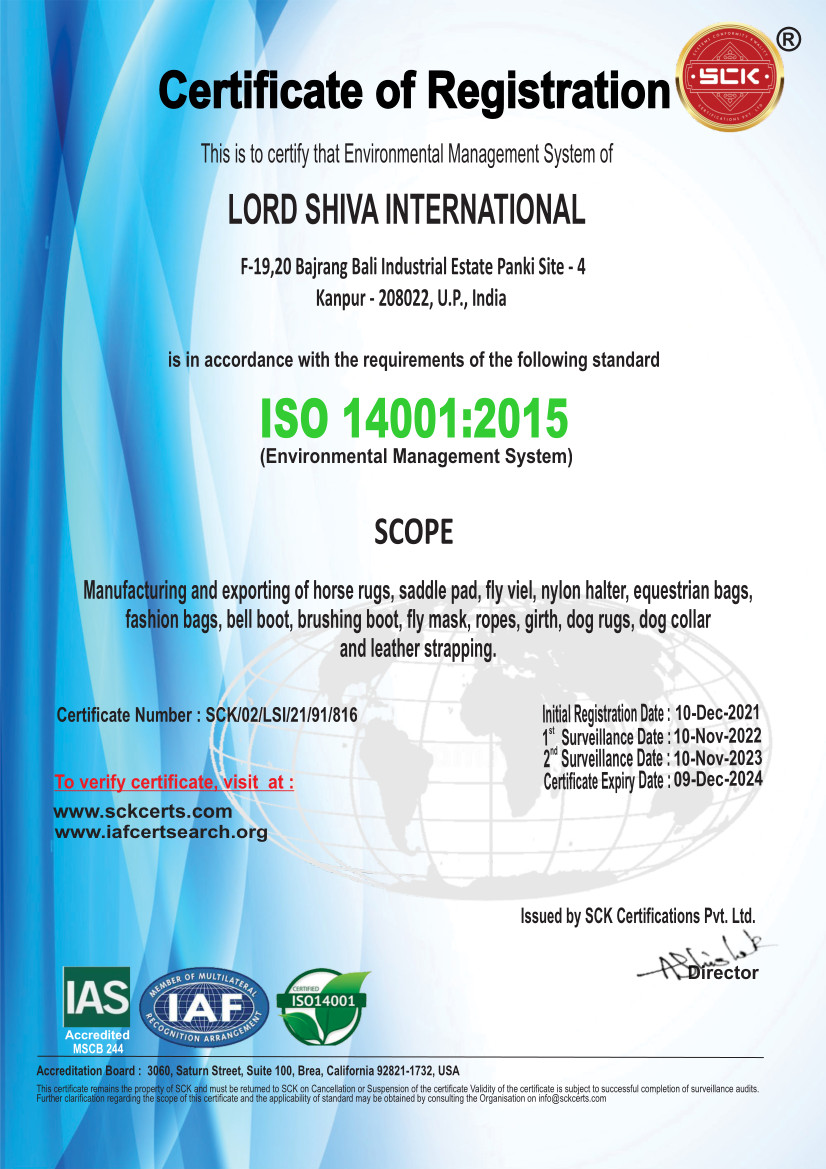

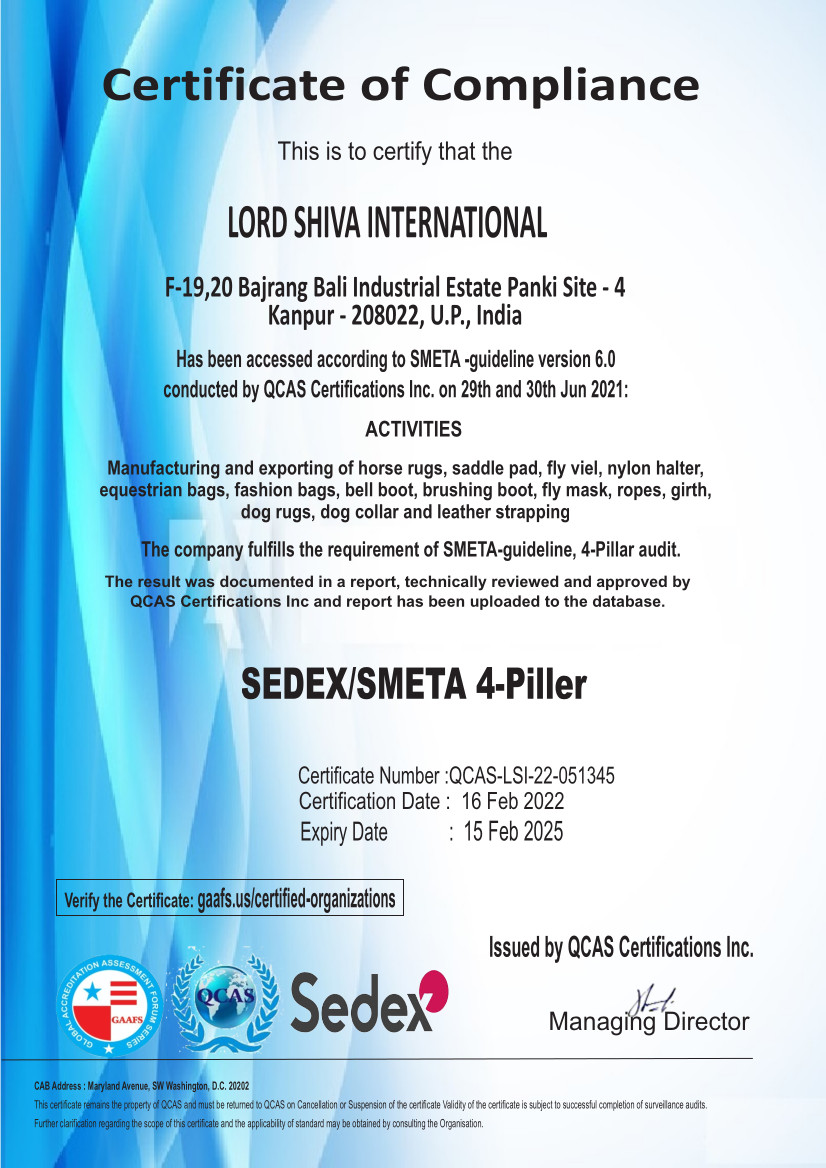

LORD SHIVA INTERNATIONAL was established in 2007 and has been a forerunner in providing world-class Leather and Non-Leather products. Our range includes Equestrian articles, Fashion Bags and Accessories, and various other utility items.

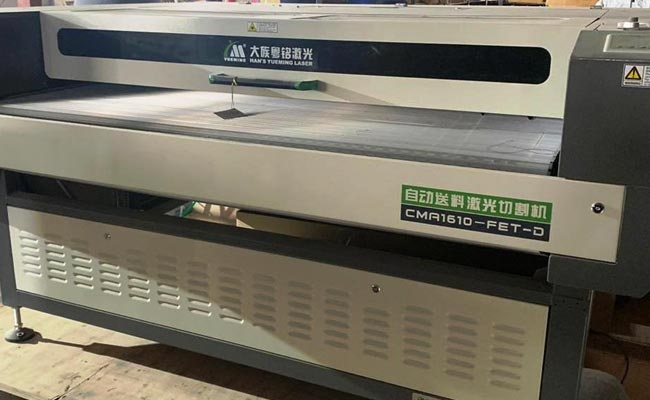

The factory is spread over 10,000 sq. Ft. in an area with a large state-of-the-art infrastructure which includes machinery and equipment that can produce the finest quality products within the stipulated time frame. The company has extremely ambitious plans for expansion that will help us stay ahead of the competition and ensure total customer satisfaction.

Currently, we cover Europe, the USA, Canada, the UK, Australia, and New Zealand and are working tirelessly to expand to the rest of the world.